Additive Manufacturing in Aerospace is transforming how we design and produce aircraft components, promising efficiency and innovation. This technique, often dubbed 3D printing, allows engineers to create complex geometries that were previously impossible with traditional manufacturing methods.

By leveraging this technology, the aerospace industry is not only reducing material waste but also significantly shortening production times, paving the way for more agile manufacturing processes and custom solutions tailored to specific needs.

Introduction to Additive Manufacturing in Aerospace

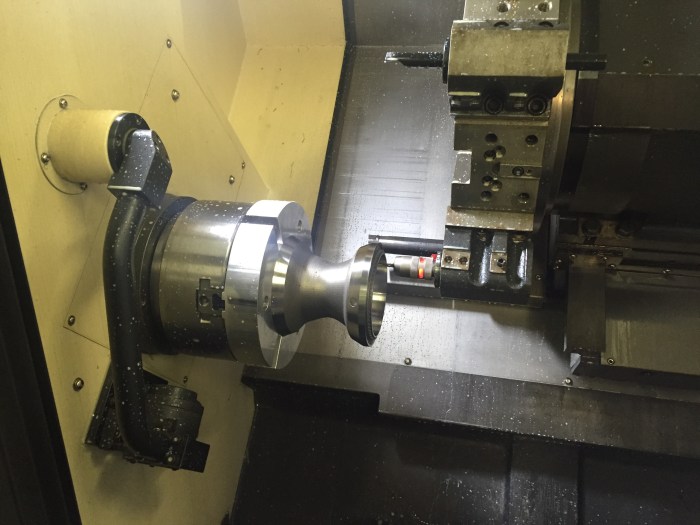

Additive manufacturing, often referred to as 3D printing, is a transformative technology that builds objects layer by layer from digital models. This innovative approach is gaining significant traction in the aerospace industry due to its ability to create complex geometries, reduce waste, and shorten production times. With the aerospace sector’s constant push for efficiency and performance, additive manufacturing stands out as a game-changer.Historically, additive manufacturing began in the 1980s, primarily for rapid prototyping.

Over the years, it has evolved to encompass a variety of materials and applications, particularly within aerospace. From initial uses for creating functional prototypes to the current production of critical components, the journey of additive manufacturing in aerospace showcases its growing importance. Early applications were limited, but advancements in technology and materials have paved the way for its integration into the manufacturing processes of leading aerospace companies.

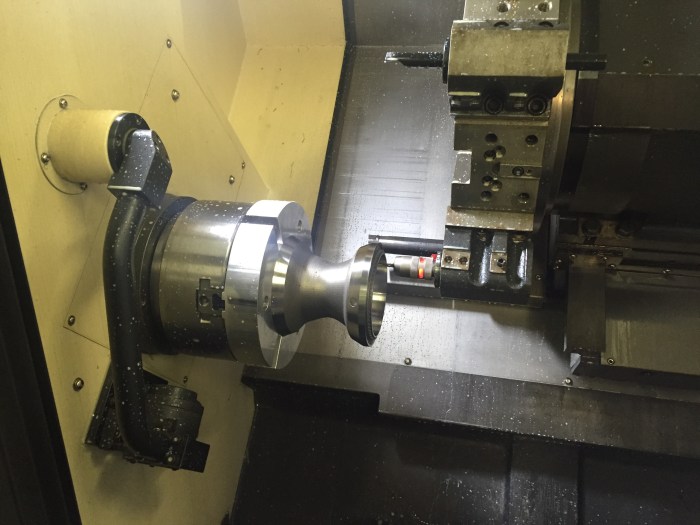

Comparison of Traditional Manufacturing Methods and Additive Manufacturing in Aerospace

Understanding the differences between traditional manufacturing and additive manufacturing is crucial for appreciating the benefits that the latter brings to the aerospace industry. Traditional manufacturing involves subtractive techniques—removing material from a solid block to create parts, which can be time-consuming and wasteful. In contrast, additive manufacturing builds parts layer by layer, drastically reducing material waste and enabling the production of highly complex designs that would be impossible with traditional methods.Key distinctions include:

- Material Waste: Traditional methods often produce significant scrap material, while additive manufacturing utilizes only the necessary material.

- Design Complexity: Additive manufacturing allows for intricate shapes and internal structures that enhance performance, which are restrictive in traditional methods.

- Production Speed: Additive manufacturing can significantly reduce lead times for part production, facilitating quicker prototyping and iteration.

- Cost-Effectiveness: For low-volume production, additive manufacturing can be more cost-effective as it eliminates the need for expensive tooling.

Notably,

the ability to create lightweight components is crucial in aerospace, where every gram saved can lead to improved fuel efficiency and performance.

This shift not only supports the design of more efficient aircraft but also enhances the ability to produce customized solutions tailored to specific operational requirements. The incorporation of additive manufacturing technologies is transforming the aerospace landscape and paving the way for further innovations that could define the future of air travel and space exploration.

Advantages of Additive Manufacturing in Aerospace

Additive manufacturing (AM), commonly known as 3D printing, is revolutionizing the aerospace industry by providing innovative solutions that enhance efficiency and performance. The shift towards AM comes with a myriad of benefits, notably in the areas of weight reduction, material efficiency, lead times, and cost-effectiveness, making it a game-changer for aerospace applications.One of the most significant benefits of additive manufacturing is its capability to create lightweight components without compromising structural integrity.

This is particularly crucial in aerospace, where every kilogram counts towards fuel efficiency and overall performance. By utilizing advanced materials and intricate designs made possible by AM, manufacturers can significantly reduce the weight of aircraft components while simultaneously enhancing their strength.

Weight Reduction and Material Efficiency

The lightweight nature of components produced through additive manufacturing stems from the ability to design complex geometries that traditional manufacturing methods cannot achieve. This process helps in minimizing material wastage, as AM uses only the necessary amount of material required to build a part.

Optimized Designs

AM allows for topology optimization, leading to the creation of parts that are tailored for specific loads and functions, ultimately reducing unnecessary mass.

Material Usage

Unlike traditional subtractive manufacturing, which involves cutting away material, AM builds parts layer by layer, maximizing the use of raw materials.

Advanced Materials

The technology supports the use of high-performance materials, including titanium and composite materials, which offer superior strength-to-weight ratios.

Reduction of Lead Times for Aerospace Components

Additive manufacturing drastically shortens the lead times for producing aerospace components. Traditional methods often involve lengthy processes of tooling and machining, which can delay production schedules. In contrast, AM can produce parts directly from digital models.

Rapid Prototyping

Engineers can quickly iterate designs and create prototypes for testing without extensive setup times, facilitating faster innovation.

On-Demand Production

Components can be produced as needed, eliminating the need for large inventories and reducing storage costs.

Supply Chain Simplification

AM can localize production, reducing logistics complexities and time associated with transporting parts.

Cost-Effectiveness of Additive Manufacturing

In terms of cost, additive manufacturing offers financial advantages over conventional manufacturing techniques, especially when considering long-term investments and operational efficiency.

Reduced Material Costs

The efficiency of material usage in AM leads to lower costs, particularly for expensive raw materials used in aerospace applications.

Labor Savings

Automating the production process with AM can reduce labor costs associated with machining and assembly.

Lower Tooling Costs

Since AM does not require expensive molds or tooling, companies can save significantly on upfront capital expenditures.In conclusion, the integration of additive manufacturing into aerospace not only brings about substantial weight reductions and material efficiencies but also streamlines production processes and reduces costs, establishing a compelling case for its continued adoption in the industry.

Materials Used in Additive Manufacturing for Aerospace

Additive manufacturing (AM) in aerospace relies on a diverse range of materials to achieve the high-performance standards demanded by the industry. The choice of materials directly influences the strength, weight, and durability of the components produced, making it crucial to understand the various options available. This section delves into the primary materials utilized in aerospace additive manufacturing, focusing on metals, polymers, and composites, while also exploring recent innovations that enhance these applications.

Metals in Additive Manufacturing

Metals are at the forefront of additive manufacturing in aerospace, primarily due to their excellent mechanical properties and ability to withstand extreme conditions. Commonly used metals include titanium, aluminum, and nickel-based superalloys. Each material offers distinct advantages:

- Titanium Alloys: Known for their high strength-to-weight ratio and corrosion resistance, titanium alloys excel in aerospace applications such as engine components and structural parts. For instance, Ti-6Al-4V is frequently used for critical components due to its impressive mechanical properties.

- Aluminum Alloys: Lightweight and abundant, aluminum is ideal for creating parts that require a balance of strength and weight savings. Aluminum alloys like AlSi10Mg are often used for creating lightweight structures, enhancing fuel efficiency in aircraft.

- Nickel-based Superalloys: These materials are designed to perform under high temperatures and stresses, making them essential for turbine engines. Alloys like Inconel 718 are utilized for their exceptional high-temperature strength and oxidation resistance.

Polymers in Additive Manufacturing

Polymers offer unique benefits in additive manufacturing, especially in lightweight applications and prototyping. They are generally easier to process and can be used for a variety of aerospace components, including interior parts and non-structural elements. Common polymers used include:

- Polyether Ether Ketone (PEEK): Renowned for its thermal stability and chemical resistance, PEEK is perfect for high-performance applications where durability and lightweight characteristics are needed.

- Polyamide (Nylon): Frequently used in rapid prototyping and manufacturing, nylon is valued for its flexibility, strength, and relative ease of processing. It is often used for fittings and non-load bearing components.

- Thermoplastic Elastomers (TPE): These materials combine the properties of rubber and plastics, making them suitable for applications requiring flexibility and resilience, catering to various aerospace needs.

Composites in Additive Manufacturing

Composite materials combine multiple constituents to achieve superior properties. In aerospace, composites are particularly beneficial for structures requiring high stiffness and low weight. Common composites include:

- Carbon Fiber Reinforced Polymers (CFRP): These composites deliver outstanding strength while maintaining a lightweight profile. Their use in aerospace structures reduces weight and enhances performance.

- Glass Fiber Reinforced Polymers (GFRP): While not as strong as CFRP, GFRPs are more cost-effective and are used in applications where high strength is less critical.

- Hybrid Composites: By combining different fibers or materials, hybrid composites can optimize mechanical properties for specific applications, leading to innovations in aircraft design.

Innovations in materials science continue to enhance the capabilities of additive manufacturing in aerospace. Research into new alloys and composite formulations focuses on improving mechanical properties, thermal resistance, and environmental sustainability. Innovations such as functionally graded materials (FGMs) cater to specific performance needs, allowing parts to have varied properties within a single component.In summary, the landscape of materials used in additive manufacturing for aerospace is rich and diverse, providing engineers with a toolkit of options to push the boundaries of design and functionality in the industry.

Additive Manufacturing Technologies in Aerospace

Additive manufacturing (AM) has revolutionized the aerospace industry by enabling the production of complex geometries and lightweight components that were previously unimaginable. This transformation is largely due to the variety of AM technologies that cater to different requirements and applications within aerospace. Understanding these technologies is crucial for aerospace engineers and manufacturers to optimize processes and improve product performance.Different additive manufacturing technologies each have unique characteristics that make them suitable for specific aerospace applications.

The most prominent technologies include Selective Laser Sintering (SLS), Stereolithography (SLA), Fused Deposition Modeling (FDM), and Directed Energy Deposition (DED). Here’s a closer look at these technologies and how they compare.

Overview of Additive Manufacturing Technologies

Each additive manufacturing technology brings distinct advantages and limitations that influence their application in aerospace. Below is a summary of the technologies, highlighting their suitability for various aerospace needs.

| Technology | Advantages | Limitations |

|---|---|---|

| Selective Laser Sintering (SLS) |

|

|

| Stereolithography (SLA) |

|

|

| Fused Deposition Modeling (FDM) |

|

|

| Directed Energy Deposition (DED) |

|

|

The choice of additive manufacturing technology depends heavily on the specific application within the aerospace sector. For instance, SLS might be preferred for functional prototypes, while SLA could be used for detailed part visualization. FDM is often chosen for rapid prototyping due to its cost-effectiveness, while DED shines in applications that need repair capabilities and material addition to existing components.

Ultimately, understanding these technologies enables aerospace manufacturers to harness the full potential of additive manufacturing in delivering innovative solutions.

Applications of Additive Manufacturing in Aerospace

Additive manufacturing (AM) has revolutionized the aerospace sector, opening up new avenues for design and production. From rapid prototyping to the production of complex components, AM offers significant advantages that traditional manufacturing methods cannot match. By enabling the creation of parts that are lighter, stronger, and more efficient, additive manufacturing is becoming a pivotal component in the aerospace industry.One of the primary applications of additive manufacturing in aerospace is in the prototyping and production of parts.

AM allows engineers to create prototypes quickly and cost-effectively, facilitating iterative design processes. This speed is crucial in an industry where time-to-market can significantly affect competitive advantage. Additionally, AM is used in the production of end-use parts, especially in areas where weight reduction is essential.

Prototyping and Production of Parts

The capacity to produce prototypes in-house accelerates testing and validation processes, enabling companies to refine designs before full-scale production. This can lead to substantial cost savings and faster project timelines. Some notable applications include:

- Engine Components: Additive manufacturing is used to create complex turbine blades that optimize performance and efficiency. These blades can incorporate intricate cooling channels that traditional methods cannot achieve.

- Brackets and Supports: Lightweight brackets produced through AM significantly reduce overall aircraft weight, contributing to fuel savings and efficiency.

- Interior Components: Custom interior parts, such as seat frames and paneling, can be manufactured to meet specific design requirements, showcasing the versatility of AM.

Creating Complex Geometries and Customized Components

Additive manufacturing thrives in its ability to produce complex geometries that enhance performance and functionality. The layer-by-layer construction process allows for designs that are not feasible with traditional manufacturing techniques. The implications of this capability are enormous, especially when considering component optimization and weight reduction.For example, AM enables the production of lattice structures that maintain strength while minimizing material use.

These structures are particularly beneficial for aerospace applications, where every gram counts. The customization offered by AM also allows manufacturers to tailor components to specific aircraft models, enhancing the fit and function of parts.

Case Studies of Successful Implementation

Several aerospace companies have successfully integrated additive manufacturing into their operations, showcasing its transformative potential:

- GE Aviation: The company has incorporated AM to produce fuel nozzles for its LEAP engine, reducing the number of parts from 18 to just one. This not only cuts production time but also enhances reliability.

- Boeing: By utilizing additive manufacturing, Boeing has produced over 60 different parts for its 787 Dreamliner, including brackets and ducting components, demonstrating the effectiveness of AM in improving production efficiency.

- Airbus: The A350 XWB program features over 1,000 3D-printed parts, including cabin components. Airbus’s focus on lightweight and complex designs has significantly benefited from additive manufacturing.

Challenges and Limitations of Additive Manufacturing in Aerospace

The aerospace industry is undergoing a transformative shift with the adoption of additive manufacturing (AM) technologies, but this shift is accompanied by numerous challenges and limitations. Understanding these hurdles is essential for stakeholders aiming to implement AM successfully in aerospace applications. The following key areas highlight the main challenges that the industry faces.

Main Challenges in Adopting Additive Manufacturing Technologies

The integration of additive manufacturing in aerospace brings various challenges that can impede its widespread adoption. These challenges include technical limitations, cost considerations, and the need for skilled personnel. The following points delineate these issues:

- Technical Limitations: Current AM technologies may struggle to meet the stringent performance and reliability requirements of aerospace applications, particularly for critical components.

- Cost Implications: While AM has the potential to lower production costs, the initial investment in equipment and materials can be significant, posing a barrier to entry for many manufacturers.

- Workforce Skills Gap: There is a shortage of trained personnel who are proficient in AM technologies, which can lead to slow adoption rates and operational inefficiencies.

Regulatory and Certification Hurdles

Navigating the regulatory landscape is a significant challenge for additive manufacturing in aerospace. The certification process for AM parts is complex and often requires extensive testing and validation to ensure compliance with safety standards.

- Certification Requirements: Aerospace components must undergo rigorous testing to gain certification, which can be time-consuming and costly, delaying the implementation of AM technologies.

- Regulatory Bodies: Different regions have varying regulations, which can complicate compliance and increase the burden on manufacturers seeking to market their AM components globally.

- Documentation and Traceability: Ensuring that all AM processes are well-documented is crucial for regulatory approval, but achieving thorough traceability can be challenging due to the complexity of AM workflows.

Quality Assurance and Standardization Issues

Quality assurance in additive manufacturing presents unique challenges, particularly as industry standards are still evolving. Ensuring consistent quality across AM-produced parts is critical for their acceptance in aerospace applications.

- Material Variability: The properties of AM materials can vary significantly based on the manufacturing process, which can lead to inconsistencies in part performance.

- Lack of Standardization: The absence of universally accepted standards for AM processes and materials can lead to discrepancies in quality and performance, making it difficult for manufacturers to ensure compliance with aerospace standards.

- Inspection Techniques: Developing effective inspection techniques for AM parts is still a work in progress, which poses challenges in verifying the integrity and reliability of components before they are deployed in aviation applications.

Future Trends in Additive Manufacturing for Aerospace

The future of additive manufacturing (AM) in the aerospace industry looks promising, with significant advancements on the horizon. As technology evolves, we can expect transformative developments that will enhance manufacturing processes, reduce lead times, and lead to innovative designs. The integration of automation and artificial intelligence (AI) will play a crucial role in shaping these advancements, making production smarter and more efficient.The aerospace sector is already witnessing a shift towards more sophisticated manufacturing techniques.

As AM becomes more widely adopted, several emerging trends and innovations are expected to have a profound impact on the industry.

Emerging Trends and Innovations

The following trends highlight the anticipated advancements in additive manufacturing for aerospace:

- Increased Use of Composite Materials: Future AM processes are likely to incorporate advanced composite materials, combining the lightweight benefits of polymers with the strength of metals.

- Enhanced AI Integration: AI could lead to smarter design processes by predicting optimal manufacturing parameters and identifying potential failures before production begins.

- Automation in Production: The integration of robotics and automated systems will streamline manufacturing workflows, reduce human error, and enhance consistency in quality.

- Digital Twin Technology: This technology allows for the creation of a virtual model of a physical object, enabling improved simulation and analysis during the design phase.

- On-Demand Manufacturing: The ability to produce parts on demand will significantly reduce inventory costs and waste, allowing for more sustainable practices within the aerospace sector.

- Collaboration with Industry 4.0: The convergence of AM with Industry 4.0 initiatives will promote smart factories, where machines communicate seamlessly and adapt to changing conditions in real time.

- Regulatory Advancements: As AM technologies mature, regulatory bodies are expected to develop clearer guidelines and standards that will facilitate certification processes for aerospace components.

The integration of automation and AI in additive manufacturing processes is poised to redefine the way aerospace components are designed and produced, setting the stage for unprecedented efficiency and innovation.

These trends illustrate the dynamic nature of additive manufacturing in aerospace, where continuous innovation will not only enhance production capabilities but also redefine the future of aircraft design and functionality. The industry’s ability to adapt to these changes will significantly influence its competitiveness in a rapidly evolving market.

Last Point

In conclusion, Additive Manufacturing in Aerospace stands at the forefront of a manufacturing revolution, offering numerous advantages that traditional methods simply can’t match. As the technology continues to evolve, we can expect exciting advancements that will further enhance its application and integration within the aerospace sector, leading to safer, lighter, and more efficient aircraft.

Essential FAQs

What is additive manufacturing?

Additive manufacturing is a process of creating objects by adding material layer by layer, typically using 3D printing technology.

How does additive manufacturing benefit the aerospace industry?

It benefits the aerospace industry by reducing weight, improving material efficiency, shortening lead times, and decreasing costs.

What materials are commonly used in aerospace additive manufacturing?

Common materials include metals, polymers, and composites, each chosen for their specific properties suited for aerospace applications.

What are the challenges of implementing additive manufacturing in aerospace?

Challenges include regulatory hurdles, quality assurance issues, and the need for standardization in manufacturing processes.

What future trends are expected in additive manufacturing for aerospace?

Future trends may include advancements in automation, AI integration, and new materials that enhance manufacturing capabilities.