Diving into the world of high-value chemicals produced for specific applications often with unique properties reveals a fascinating landscape of innovation and specialized uses. These chemicals stand out in various industries due to their unique characteristics that enhance performance and efficiency in ways standard chemicals simply can’t match.

From pharmaceuticals to materials science, high-value chemicals play crucial roles in developing advanced solutions tailored to specific needs. Their unique properties not only set them apart but also drive advancements across diverse sectors, making them indispensable in today’s technological landscape.

Introduction to High-Value Chemicals

High-value chemicals are specialized substances that possess unique properties and are produced for specific applications across various industries. These chemicals are significant because they often serve as essential components in advanced materials, pharmaceuticals, agriculture, and other critical sectors, enhancing product performance and sustainability. The distinction between high-value chemicals and standard chemicals lies in their complexity, functionality, and the innovative processes required for their production.

High-value chemicals often exhibit tailored characteristics, such as high purity, specific reactivity, or unique physical properties, making them indispensable in specialized applications. Examples include pharmaceutical intermediates, specialty polymers, and agrochemicals, each serving pivotal roles in their respective fields.

Key Characteristics of High-Value Chemicals

High-value chemicals are characterized by several key traits that set them apart from conventional chemicals. Understanding these characteristics is crucial for their effective application in various industries.

- Complex Structure: High-value chemicals often feature intricate molecular structures that contribute to their unique properties and functionalities.

- Specific Functionality: They are designed for particular uses, such as acting as catalysts, active pharmaceutical ingredients, or advanced materials.

- High Purity: The production processes for high-value chemicals typically yield products with a higher purity level compared to standard chemicals, which is crucial for sensitive applications.

- Customization: These chemicals can be tailored to meet the specific requirements of a given application, allowing for enhanced performance and efficiency.

- High Economic Value: Due to their specialized applications and the technologies involved in their production, high-value chemicals often command a premium price in the market.

Examples of High-Value Chemicals and Their Applications

Numerous high-value chemicals are utilized in various industries, showcasing their importance in driving innovation and quality. Each example represents a distinct application with significant implications for product development and performance.

- Pharmaceutical Intermediates: These chemicals are crucial in the synthesis of active pharmaceutical ingredients (APIs), playing a vital role in drug development and formulation.

- Specialty Polymers: Used in high-performance applications such as adhesives, coatings, and sealants, these polymers exhibit superior properties compared to conventional materials.

- Agricultural Chemicals: High-value agrochemicals, such as pesticides and fertilizers, are designed to enhance crop yield and reduce environmental impact through targeted action.

- Biochemicals: Enzymes and bio-based products used in food processing, biofuels, and waste management highlight the growing movement toward sustainable practices.

- Functional Materials: Chemicals designed for specific applications, such as sensors, catalysts, and electronic materials, are integral to advancing technology and innovation.

Unique Properties of High-Value Chemicals

High-value chemicals are distinguished by their unique properties that cater to specific applications across various industries. These properties not only enhance their performance but also contribute to efficiency gains, making them indispensable in modern manufacturing and production processes. Understanding these unique attributes is crucial for industries looking to innovate and optimize their operations.The chemical composition and molecular structure of high-value chemicals often provide them with distinct advantages over traditional chemicals.

These advantages can be seen in aspects such as reactivity, stability, solubility, and specific functional characteristics that allow them to perform exceptionally well in their designated roles. For instance, high-value chemicals may exhibit enhanced thermal stability, which is critical in applications requiring resistance to heat and degradation over time. This leads to longer product lifespans and reduced replacement costs.

Performance Advantages of Unique Properties

The unique properties of high-value chemicals directly influence their performance in various applications. Here are some notable advantages:

- Enhanced Reactivity: High-value chemicals often feature functional groups that enable faster and more efficient reactions. This is beneficial in pharmaceutical synthesis, where quicker reaction times can lead to reduced production costs and increased output.

- Specificity: Certain high-value chemicals are engineered to have specific interactions with target molecules, enhancing selectivity in processes like drug formulation. This specificity minimizes side effects and maximizes therapeutic efficacy.

- Improved Solubility: Many high-value chemicals possess unique solubility properties that allow them to dissolve in various solvents, facilitating better formulations in cosmetics and personal care products.

- Biodegradability: Some high-value chemicals are designed to be environmentally friendly, breaking down naturally and reducing ecological impact. This is especially relevant in green chemistry and sustainable production practices.

- Thermal Stability: High-value chemicals often maintain their integrity under extreme temperatures, making them suitable for high-performance applications in electronics and aerospace.

The impact of these properties on efficiency and performance is significant. For example, in the field of agriculture, high-value chemicals like advanced pesticides or fertilizers demonstrate improved crop yields owing to their specialized formulations that enhance nutrient absorption in plants. In contrast, conventional chemicals may lack these tailored attributes, resulting in less effective agricultural practices.In summary, the unique properties of high-value chemicals not only provide a competitive edge in their respective applications but also pave the way for innovations that address current challenges across various industries.

Their superior performance capabilities underscore the importance of investing in the development and use of these specialized chemicals.

Applications of High-Value Chemicals

High-value chemicals play a pivotal role across numerous industries by providing specific functionalities that enhance product performance and meet niche market needs. Their unique properties allow for tailored applications that traditional chemicals may not offer, making them indispensable in modern manufacturing and production processes.Various industries utilize high-value chemicals to optimize their offerings, from pharmaceuticals to agriculture and materials science. Each sector has its requirements, leading to a diverse range of applications that highlight the versatility and importance of these specialized compounds.

Industry Utilization of High-Value Chemicals

Understanding how different industries leverage high-value chemicals can shed light on their essential contributions. Below is a table that summarizes specific applications alongside the corresponding high-value chemicals utilized in each sector.

| Industry | Application | High-Value Chemicals |

|---|---|---|

| Pharmaceuticals | Synthesis of active pharmaceutical ingredients (APIs) | Biopharmaceuticals, APIs like Ibuprofen |

| Agriculture | Production of fertilizers and pesticides | Nitrogen-based fertilizers, Herbicides like Glyphosate |

| Materials Science | Creation of advanced polymers | Polycarbonate, Polyethylene Terephthalate (PET) |

| Food and Beverage | Flavor and fragrance compounds | Vanillin, Ethyl Vanillin |

| Cosmetics | Active ingredients for skin care | Hyaluronic Acid, Retinol |

Case Studies Demonstrating Successful Applications

Real-world applications of high-value chemicals showcase their impact on industry innovation and efficiency. For instance, in the pharmaceutical industry, the development of biologics has revolutionized the treatment of chronic diseases. These biologics, derived from living organisms, exemplify high-value chemicals that provide targeted therapy, leading to improved patient outcomes.In agriculture, the use of nitrogen-based fertilizers has dramatically increased crop yields. For example, urea, a high-value nitrogen fertilizer, has become crucial for maximizing food production globally.

Its application in various soil types has been optimized through research, demonstrating the role of high-value chemicals in sustainable agricultural practices.Materials science has also benefitted significantly from high-value chemicals. The introduction of polycarbonate in manufacturing lightweight and durable products has transformed the production of eyewear lenses and safety equipment. This polymer’s unique properties allow for high impact resistance and optical clarity, making it a popular choice across various applications.Overall, high-value chemicals serve as the backbone for innovative solutions in multiple industries, driving advancements that address modern challenges while improving efficiency and performance.

Production Methods for High-Value Chemicals

The production of high-value chemicals involves a variety of advanced techniques that enable the synthesis of compounds with unique properties tailored for specific applications. These methods not only enhance efficiency and yield but also focus on sustainability and safety in chemical manufacturing. Understanding these production methods is crucial for industries aiming to innovate and meet specific market demands.The main methods for producing high-value chemicals include chemical synthesis, biotechnological processes, and green chemistry techniques.

Each of these methods utilizes distinct processes that optimize the efficiency and effectiveness of chemical production while minimizing environmental impact.

Chemical Synthesis

Chemical synthesis encompasses traditional techniques that have been the backbone of high-value chemical production for decades. The key processes involved in chemical synthesis often include:

Catalysis

Catalysts are substances that increase the rate of a chemical reaction without being consumed. They can be homogeneous (same phase as reactants) or heterogeneous (different phase), and they play a crucial role in the production of many high-value chemicals by lowering activation energy and enhancing selectivity.

Fractional Distillation

This process separates liquid mixtures into their components based on differences in boiling points. It’s commonly used to purify and isolate specific chemicals from crude oil or other mixtures.

Hydrogenation

A specific type of reaction where hydrogen is added to unsaturated organic compounds, typically in the presence of a catalyst. This method is vital for producing various pharmaceutical and agrochemical products.

Electrochemical Synthesis

Utilizing electrical energy to drive chemical reactions. This method is gaining traction for producing high-value chemicals in an environmentally friendly manner.

Biotechnological Processes

Biotechnological processes leverage biological systems, such as microorganisms and enzymes, to produce high-value chemicals. These processes can be highly specific and environmentally friendly. Some notable methods include:

Fermentation

This natural process involves using microorganisms to convert carbohydrates and sugars into chemicals like ethanol, organic acids, and biopolymers. For instance, the fermentation of corn to produce lactic acid is widely utilized in the production of biodegradable plastics.

Enzymatic Reactions

Enzymes can catalyze specific reactions under mild conditions, leading to the production of valuable chemicals. This method is significant in the pharmaceutical industry for synthesizing complex molecules.

Synthetic Biology

This innovative approach combines engineering principles with biology to design and construct new biological parts, devices, and systems. A classic example includes the engineering of yeast to produce artemisinin, an anti-malarial drug.

Innovative Green Chemistry Techniques

Green chemistry focuses on designing chemical processes that reduce or eliminate the use and generation of hazardous substances. This approach encompasses a range of techniques, including:

Solvent-Free Reactions

Conducting chemical reactions without solvents can significantly reduce environmental impact. For example, mechanochemistry uses mechanical force to bring reactants together, leading to high-value chemicals without traditional solvents.

Supercritical Fluid Technology

Utilizing supercritical fluids, such as carbon dioxide, as solvents can enhance extraction and reaction processes. This method is often used in the extraction of essential oils and natural products.

Photochemical Reactions

These reactions use light energy to induce chemical transformations. Photocatalysis is a growing field that is being explored for producing chemicals from renewable sources.

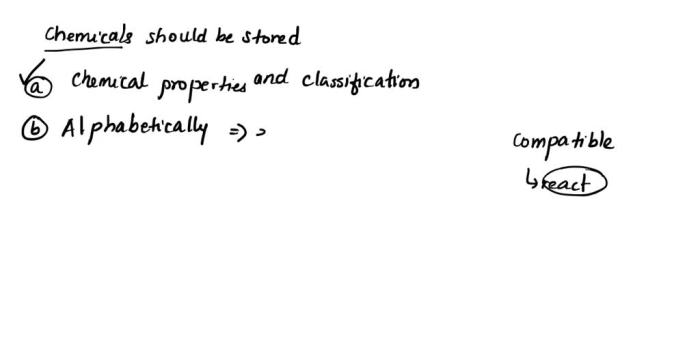

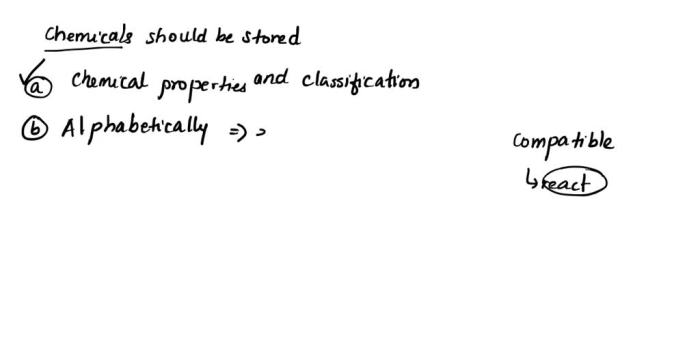

Illustrative Diagram of Production Process

To aid in understanding the production methods of high-value chemicals, here’s a simplified step-by-step representation of a generic chemical synthesis process:

1. Raw Material Procurement

Sourcing of raw materials including hydrocarbons, biomass, or substrates for fermentation.

2. Reaction Setup

Preparation of the reaction environment, including catalysts and necessary conditions (temperature, pressure).

3. Chemical Reaction

Initiating the reaction where reactants are transformed into products through various methods (catalytic, enzymatic, etc.).

4. Separation and Purification

Using techniques such as distillation or crystallization to isolate the desired high-value chemicals from by-products and unreacted materials.

5. Quality Control

Testing the final product to ensure it meets specified standards and purity levels.

6. Distribution

Packaging and distributing the high-value chemicals to end-users or for further processing.This diagram illustrates the sequential steps taken in the production of high-value chemicals, highlighting the complexity and precision involved in modern chemical manufacturing processes.

Economic Impact of High-Value Chemicals

The economic impact of high-value chemicals in industry is significant, with their unique properties transforming various sectors. By adding value to raw materials, these chemicals enable enhanced efficiency, reduced costs, and the development of innovative products. The growing demand for high-value chemicals is reshaping market dynamics and creating financial opportunities across multiple industries.High-value chemicals are essential in driving economic growth due to their diverse applications.

Their production not only supports existing industries but also fosters new markets and technologies. The profitability of high-value chemicals stems from their capacity to create specialized products that meet niche market needs. This section explores the economic benefits and market trends associated with these chemicals.

Market Trends and Growth Potential

The market for high-value chemicals is experiencing robust growth, driven by increasing demand in various applications, including pharmaceuticals, agriculture, and specialty materials. This growth is characterized by a few key trends:

1. Rising Demand in Pharmaceuticals

The pharmaceutical sector is one of the largest consumers of high-value chemicals, with sales projected to reach over $1 trillion by 2025. This demand is fueled by the need for innovative treatments and precision medicines.

2. Sustainable Practices

Industries are increasingly adopting green chemistry principles to produce high-value chemicals, leading to eco-friendly products that appeal to environmentally conscious consumers. This shift is evident in the bio-based chemical market, which is expected to grow by 10% annually.

3. Advanced Production Technologies

Innovations like biotechnology and nanotechnology are enhancing production efficiency, reducing costs, and improving product quality. For example, biocatalysis in chemical synthesis has shown to reduce energy consumption by up to 50%.

4. Global Market Valuation

The global high-value chemicals market was valued at approximately $600 billion in 2020 and is anticipated to grow at a CAGR of around 5.5% over the next decade. This growth presents substantial investment opportunities.

High-value chemicals play a pivotal role in economic development, providing jobs and fostering innovation.

The revenue generated from specific sectors indicates the economic significance of high-value chemicals. For instance, the petrochemical industry, a major supplier of high-value chemicals, reported revenues exceeding $1 trillion in 2022. In the agricultural sector, high-value fertilizers and agrochemicals contribute approximately $300 billion in global sales annually. Additionally, the specialty chemicals market, which includes high-value products used in coatings, plastics, and adhesives, is projected to reach $1 trillion by 2025.The economic contributions of high-value chemicals extend beyond direct revenue generation.

They also stimulate job creation in research and development, manufacturing, and distribution, fostering a skilled workforce and promoting technological advancements. This multifaceted impact underscores the vital role these chemicals play in modern economies and their potential to drive future growth.

Environmental Considerations

The production and utilization of high-value chemicals come with significant environmental implications that necessitate careful consideration. As the demand for these unique materials grows, so does the need to assess their environmental footprint, including the ecological impact of their production processes, usage, and disposal. This section explores the various environmental implications associated with high-value chemicals, highlights sustainable practices, and discusses the regulatory frameworks that govern their production.

Environmental Implications of High-Value Chemical Production

High-value chemicals can pose various environmental challenges, including air and water pollution, greenhouse gas emissions, and the depletion of natural resources. The production processes often require substantial energy and raw materials, leading to a significant carbon footprint. For instance, traditional petrochemical methods can release volatile organic compounds (VOCs) and other harmful pollutants into the environment.

The environmental impact can be extensive, affecting ecosystems and human health.

To mitigate these effects, industries are increasingly adopting sustainable practices. This includes reducing waste generation, utilizing cleaner production technologies, and optimizing resource efficiency.

Sustainable Practices in Production

Transitioning to sustainable production methods is crucial for reducing the environmental impact of high-value chemicals. Here are some notable practices being implemented:

- Green Chemistry: This approach focuses on designing chemical products and processes that minimize hazardous substances. The twelve principles of green chemistry, such as waste prevention and energy efficiency, guide the development of safer alternatives.

- Biotechnology: Biotechnological methods employ microorganisms in the synthesis of high-value chemicals, often yielding fewer byproducts and requiring less energy than traditional chemical synthesis.

- Recycling and Upcycling: Utilizing waste materials as feedstocks for chemical production reduces resource consumption and promotes circular economy principles.

- Sourcing Renewable Feedstocks: Using bio-based feedstocks instead of fossil fuels minimizes carbon emissions and reduces reliance on non-renewable resources.

These sustainable practices not only lessen the environmental impact but also enhance the economic viability of producing high-value chemicals.

Regulations and Policies Impacting Production

Regulatory frameworks play a pivotal role in shaping the production landscape for high-value chemicals. Governments and international bodies have established various policies aimed at minimizing environmental risks associated with chemical production. For example, regulations such as the REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) in the European Union enforce stringent safety assessments on chemical substances, compelling manufacturers to disclose potential environmental and health impacts.

Additionally, various countries are implementing stricter emissions standards and encouraging the adoption of environmentally-friendly technologies through incentives and funding programs.

Effective regulation ensures that high-value chemicals are developed responsibly, balancing industrial growth with environmental protection.

By aligning production practices with these regulations, companies can foster sustainable development while maintaining compliance and enhancing their reputational standing.

Future Trends in High-Value Chemical Production

As the landscape of chemical production evolves, high-value chemicals are poised to play a crucial role in various industries. The increasing demand for sustainable and efficient production methods has led to significant advancements in technology, particularly in biotechnology and nanotechnology. These trends are not only reshaping the methods of production but also influencing the types of chemicals being developed for specific applications.Emerging technologies are paving the way for innovative solutions in high-value chemical production.

One of the most significant trends is the integration of biotechnology, which utilizes biological systems and organisms to create chemicals that were previously difficult or impossible to synthesize chemically. Additionally, nanotechnology is enabling the development of new materials with unique properties that enhance functionality and performance across various applications. Together, these technologies are leading to the creation of high-value chemicals that are more efficient, environmentally friendly, and tailored to meet specific needs.

Role of Biotechnology and Nanotechnology

Biotechnology plays a vital role in the production of high-value chemicals by harnessing living organisms or enzymes to facilitate chemical reactions. This method offers several advantages, including lower energy consumption, reduced waste production, and the ability to create complex molecules that are challenging to synthesize using traditional methods. For instance, microorganisms are being engineered to produce biofuels, pharmaceuticals, and biodegradable plastics, showcasing the versatility of biotechnological applications.Nanotechnology also significantly contributes to the development of high-value chemicals by manipulating materials at the molecular or atomic level.

This allows for the creation of novel materials with enhanced properties, such as increased strength, lighter weight, or superior chemical resistance. For example, nanoscale catalysts can improve reaction rates, making chemical processes more efficient and cost-effective. The combination of these technologies is anticipated to produce high-value chemicals that offer improved performance and sustainability.

Potential High-Value Chemicals in the Next Decade

The landscape of high-value chemicals is expected to evolve in the coming years, driven by ongoing research and development. The following list highlights some potential high-value chemicals that may emerge, along with their anticipated applications:

- Biosurfactants: These eco-friendly surfactants derived from microbial sources can replace traditional surfactants in cleaning products and cosmetics.

- Bio-based Polymers: Polymers produced from renewable resources, such as polylactic acid (PLA), are likely to gain traction in packaging and textiles.

- Advanced Bioplastics: Innovations in bioplastics will provide alternatives to conventional plastics, offering biodegradability and reduced environmental impact.

- Smart Materials: Materials that respond to external stimuli (e.g., temperature, light) will find applications in biomedical devices and coatings.

- Novel Pharmaceuticals: Targeted drug delivery systems utilizing nanoparticles are expected to revolutionize therapeutic applications.

- Green Solvents: Solvents produced through bio-based processes will become popular in various industries, reducing the reliance on traditional solvents that are harmful to the environment.

The emergence of these high-value chemicals will not only transform existing markets but also create new opportunities in sectors such as healthcare, environmental management, and materials science. As these innovations take shape, they will play a pivotal role in promoting sustainability and efficiency in chemical production, aligning with global efforts to minimize environmental impact.

Challenges in the High-Value Chemical Sector

The high-value chemical sector, while promising and innovative, faces a multitude of challenges that can hinder growth and efficiency. These challenges range from operational hurdles to external pressures like regulatory compliance. Understanding these difficulties is crucial for stakeholders to navigate the landscape effectively and to implement viable solutions.One of the primary challenges faced by manufacturers of high-value chemicals is the complexity of production processes.

This complexity often translates into increased costs and longer time frames for product development. Furthermore, high-value chemical manufacturers must contend with fluctuating raw material prices, which can directly impact profitability.

Regulatory Hurdles and Compliance Issues

Manufacturers operate in a highly regulated environment that mandates adherence to strict safety and environmental standards. These regulations can vary considerably by region and product type, adding layers of complexity to compliance efforts. The following points highlight some of the critical regulatory hurdles:

- Safety Regulations: Stringent safety guidelines are in place to protect workers and consumers from hazardous materials.

- Environmental Impact Assessments: Regulatory bodies require comprehensive assessments to evaluate the environmental impact of chemical production.

- Product Registration and Approval: Chemicals often require extensive testing and approval before they can be marketed, prolonging time to market.

Navigating these regulations requires a thorough understanding of the legal landscape and the potential implications for business operations.

Strategies for Overcoming Challenges

To effectively tackle the challenges in the high-value chemical sector, manufacturers can adopt several strategic approaches. Implementing the following practices can enhance operational efficiency and compliance:

- Investment in Technology: Utilizing advanced technologies such as automation and data analytics can streamline production processes, reduce costs, and improve compliance tracking.

- Collaboration with Regulatory Bodies: Engaging proactively with regulatory authorities can help manufacturers stay ahead of compliance requirements and influence the development of realistic regulations.

- Continuous Training and Development: Providing ongoing training for employees on safety and compliance can significantly reduce the risk of regulatory breaches and enhance workplace safety.

These strategies can not only mitigate challenges but also foster innovation and competitiveness in the high-value chemical market. By addressing both operational and regulatory hurdles, manufacturers can position themselves for long-term success.

Ultimate Conclusion

In summary, high-value chemicals are not just substances; they are pivotal to advancements in various industries, offering unique properties that enhance performance and sustainability. As we move forward, these chemicals will continue to shape the future, presenting both opportunities and challenges that will require innovative solutions and responsible practices.

Clarifying Questions

What are high-value chemicals?

High-value chemicals are specialized substances produced for specific applications, characterized by unique properties that enhance performance in various industries.

How do high-value chemicals differ from standard chemicals?

High-value chemicals possess distinct characteristics that provide superior efficiency and performance in their applications compared to standard chemicals.

What industries utilize high-value chemicals?

Industries such as pharmaceuticals, agriculture, and materials science are major users of high-value chemicals to meet specific demands.

What are the environmental impacts of high-value chemical production?

The production of high-value chemicals can have environmental implications, but sustainable practices and regulations aim to mitigate these impacts.

What trends are emerging in high-value chemical production?

Emerging trends include advancements in biotechnology and nanotechnology, which are paving the way for new high-value chemical innovations.